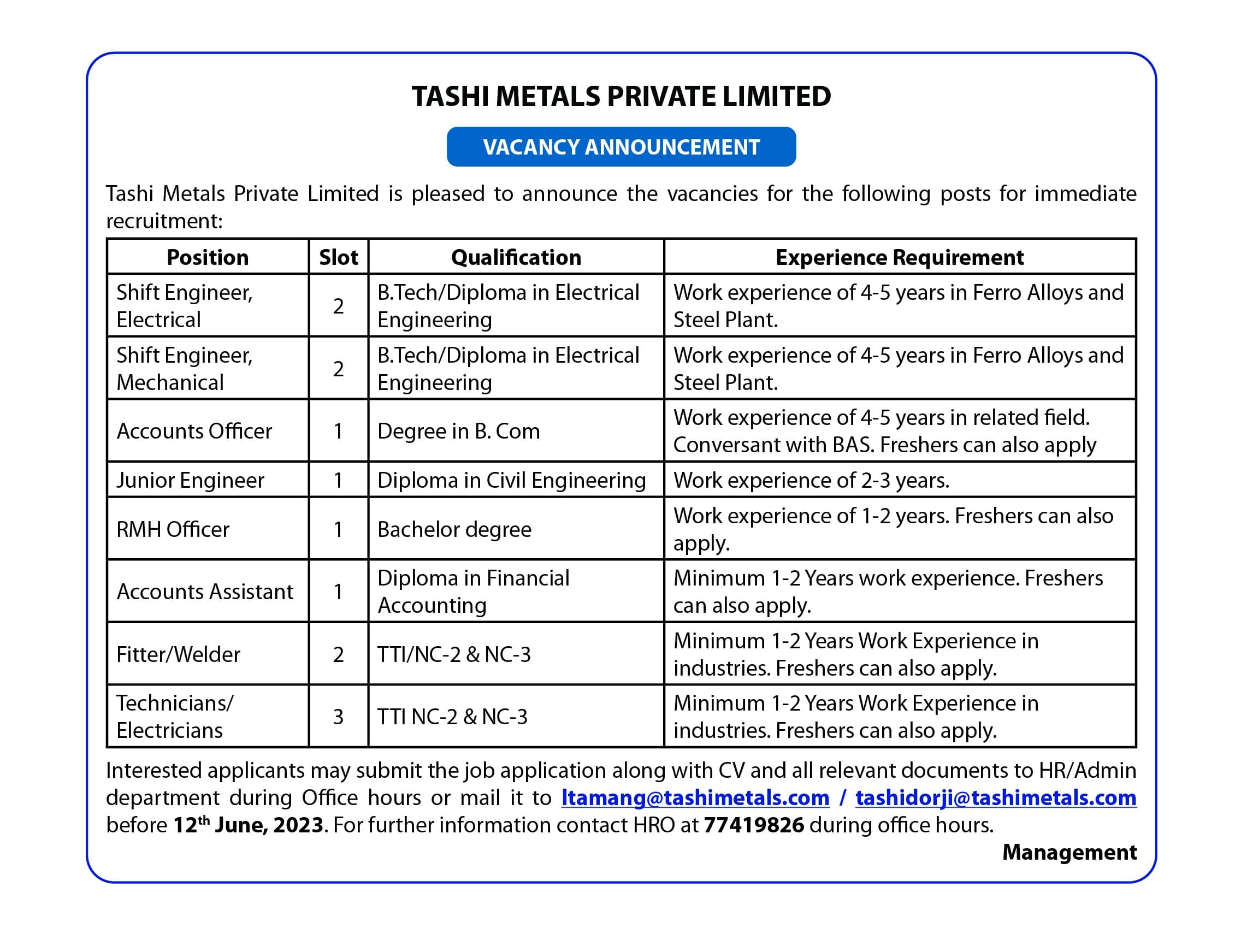

Currently, Punatsangchhu Hydropower Authority I & II have slashed their cement requirement to 165MT against their normal requirement of 700MT per day. Apart from the chief reason, maintenance works at the dam site, another issue the projects are facing is cement quality that often does not meet required standards.

PHPA II has been running short of cement for some time now. It requires 2.5mn tons of cement for concrete placement.

The Managing Director (MD) of PHPA, R N Khazinchi, said that the specification of cement often alters.

He said at times the batch of cement reaching the project meet requirements while at other times it does not and has to be sent back.

Once the cement reaches the project, it is tested in the hydropower projects’ laboratory every day.

However, the Chief Executive Officer (CEO) of Dungsam Cement Corporation Limited (DCCL), which supplies cement to the hydropower projects, Sonam Jigme, said the projects require cement, which is fast setting so that the projects can be completed on time.

“There would be little alteration in specification of the cement,” he said.

The CEO said that while DCCL produces cement of superior quality, there have been instances where the project contractors have expressed concern regarding meeting of specific required parameters.

He added these concerns have been redressed with the company’s standard operating procedure confirming to ISO requirements.

“Any such instances have been duly resolved to the utmost satisfaction of the project contractors,” said the CEO.

DCCL CEO also said that the company is committed to produce and supply cement confirming to Bureau of Indian Standard (BIS) and Bhutan Standard Bureau (BSB) norms adding that cement being a mass-produced and process-based product, no company can boast of zero instances of quality complaints irrespective of its stature.

DCCL has been supplying cement to hydroelectric contractors for the past three years and while most of the time the project contractors have expressed complete satisfaction regarding supplies, logistics has been a major constraint in the hilly terrain of the project, the CEO added.

Meanwhile, PHPA MD said when the projects face shortage of cement supply, they have to import from India.

“But if we are to tie up with Indian suppliers, firstly we have to get government approval. We have to register with the suppliers and by the time registration is finalized, rates for cement changes in the market. We also need to seek tax exemption as concession for the projects.”

RN Khazinchi said that because of this, the projects need a long-term agreement for one year or so with the Indian suppliers so that they can supply at committed rates while the projects can also avail tax exemption.

The MD said that provided there is continuous supply of cement from DCCL with requisite specifications, the projects can be completed by 2021.

“We cannot store the cement since shelf life is only three months, and the supply has to be continuous,” he said.

In the past DCCL supplied cement to the projects by tying up with Penden Cement Authority Limited as well as Dalmia Cement in India.

DCCL also supplies to Mangdechhu Hydroelectric Project (MHEP) and Tangsibji projects. DCCL supplies 628MT of cement per day to MHPA and Tangsibji project.

Most of this goes to MHEP since Tangsibji hydropower project is in the initial stages and the demand is erratic and low as of now.

Sonam Jigme said that export sales are the core business interest for DCCL. After the completion of the hydropower projects in the near future, DCCL will be required to sell 75-80% of the produce to export market. The current market includes entire northeast states including north Bengal and Sikkim.

DCCL is capable of producing 4,130MT of cement a day translating to 1.36mn tons per annum.

Dechen Dolkar from Thimphu