Industries in Pasakha are looking for alternative destinations to dispose by-products from raw materials since the Indian Customs has asked Indian suppliers to refrain from procuring these from Bhutan. .

The primary cause for this is because a certificate of origin needs to be produced for these products, which do not originate in Bhutan.

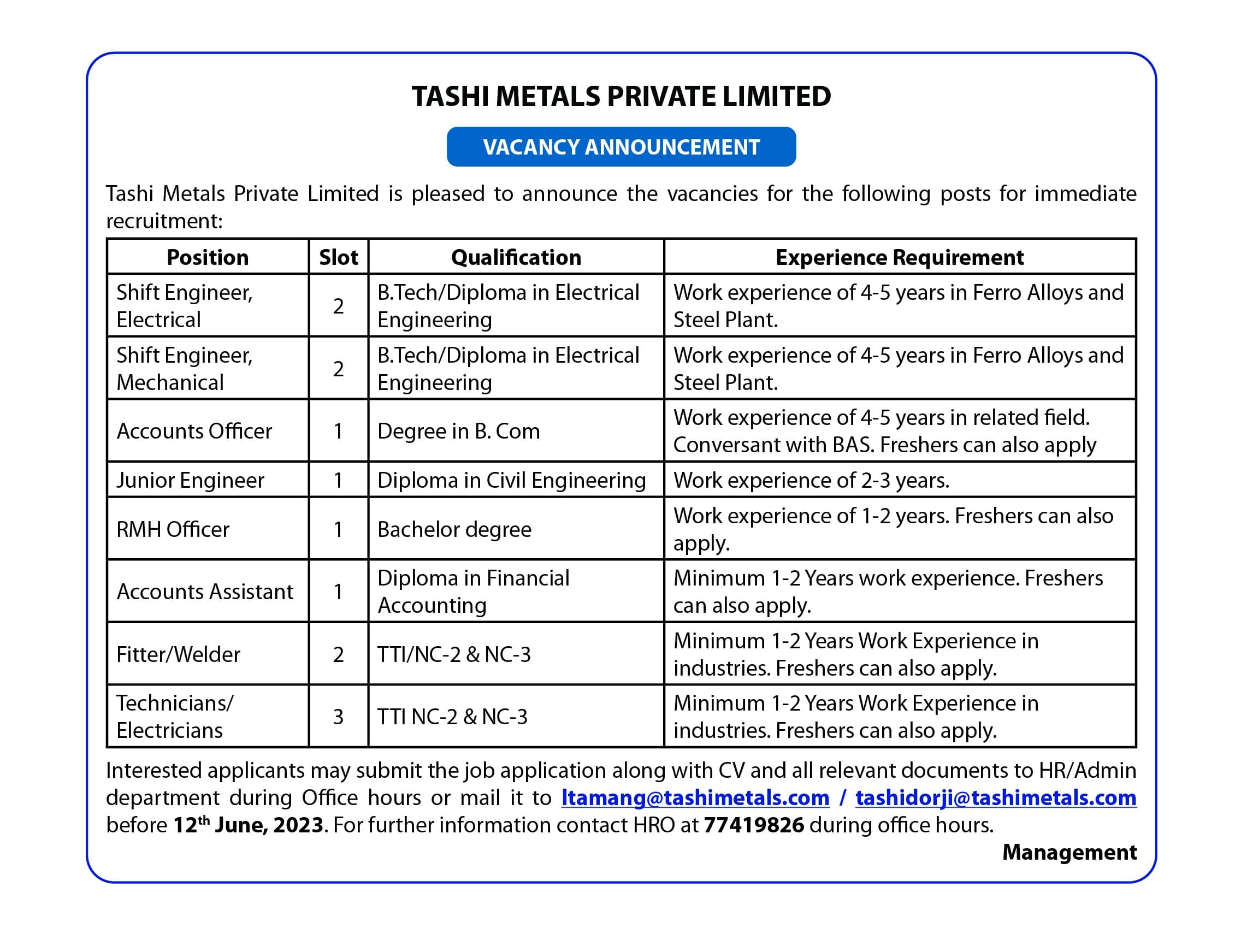

The by-products are mostly generated from raw materials for ferrosilicon industries like charcoal and Nangal coal fines. The resulting powder used to be exported back to India since it did not have much use in the country. It was used as manure in tea gardens and for producing incense in India. Also, Nangal coal fines are used in clay bricks manufacturing plants in India. Lime fines, carbide dust, Low Ash Metallurgical Coke (LAMC) and scraps are other wastes from these plants. Till now these materials were exported to India through the suppliers.

The industries use coal bigger than 6mm as raw material to produce Ferrosilicon; sizes smaller than this remain stocked in the plant. “When such products are brought in bulk, in the process of transportation, these products get crushed and become unusable. So we used to export back to India as it is used for other purposes. But now these unwanted products will remain in the plants without a place to dump,” said the Manager of Ugyen Ferro Alloys Limited.

There are more than eight Ferrosilicon industries in Pasakha Industrial Estate. About 3,000 MT of such fines from charcoal, Nangal coal and LAMC are generated in the plants every month. “If not disposed properly, the impact could be huge,” Druk Ferro Alloys Limited’s Giri Dhari Saha said. Druk Ferro generates about 300 MT of such wastes a month.

All the companies used to export back these wastes till now as they are environmentally hazardous and are not much used in other industries. Some contractors procure Quartz gravels from the industries for construction purposes but not all. A Senior Manager of Bhutan Carbide and Chemicals Limited, Chencho Norbu, said that the export so far has been serving dual purposes for the industries in earning extra income and conserving the environment. “We are confused where to dispose the wastes,” said Chencho Norbu.

Steel and metal scraps are consumed by steel industries within the country. But disposing off carbonaceous fines is a problem. “In no way are these fines used in Bhutan. There is no domestic market for these products, except a few,” said an official from Bhutan Ferro Alloys Limited.

There are ample buyers from India for the products. But right now, Indian importers are not taking back these by-products. Almost 15% of entire raw materials comprise fines, which cannot be used due to size restriction in the plants. The plant requires minimum 6mm of the product as raw material.

However, Ugyen Ferro Alloys Limited (UFAL) has plans to install a machine to make desired lumps of the fines to reuse as charcoal. The company has already submitted the proposal to the relevant agencies and is waiting for approval. “Though it’s not a major issue right now, if left unchecked, it could have a huge impact in the country in the long run. We are planning to reuse the by-products mainly as charcoal,” said Commercial General Manager of UFAL Manush Sharma.

Krishna Ghalley from Phuentsholing